The PDCA (Plan-Do-Check-Act) Cycle was invented by Walter A. Shewhart during the 1920s at the Bell Telephone Laboratories. The PDCA cycle is a systematic and iterative approach used in various fields to improve processes, solve problems, and achieve continuous improvement, until the cycle repetition has solved the problem. This cycle, also known as the Deming Cycle or the Shewhart Cycle. The PDCA approach was later on revised and popularized in the 1950s by the father of quality control, W. Edwards Deming into PDSA or Plan-Do-Study-Act. Deming felt that “Study” was a better fit than “Check” since the check step of PDCA was deemed as inspection rather than analysis over the methodology of problem solving.

In this article, we will talk about the process of PDCA (Plan-Do-Check-Act), PDSA (Plan-Do-Study-Act), and how it can aid to improve your business processes.

TL;DR / Key Points of PDCA

- PDCA is a problem solving methodology that involves four steps: Plan, Do, Check, Act

- PDSA is derived from PDCA, revised by W. Edwards Deming involves four steps: Plan Do, Study, Act.

- PDCA is a continuous improvement solution, efficiently evolving and optimizing business processes over time.

What is the Process of PDCA

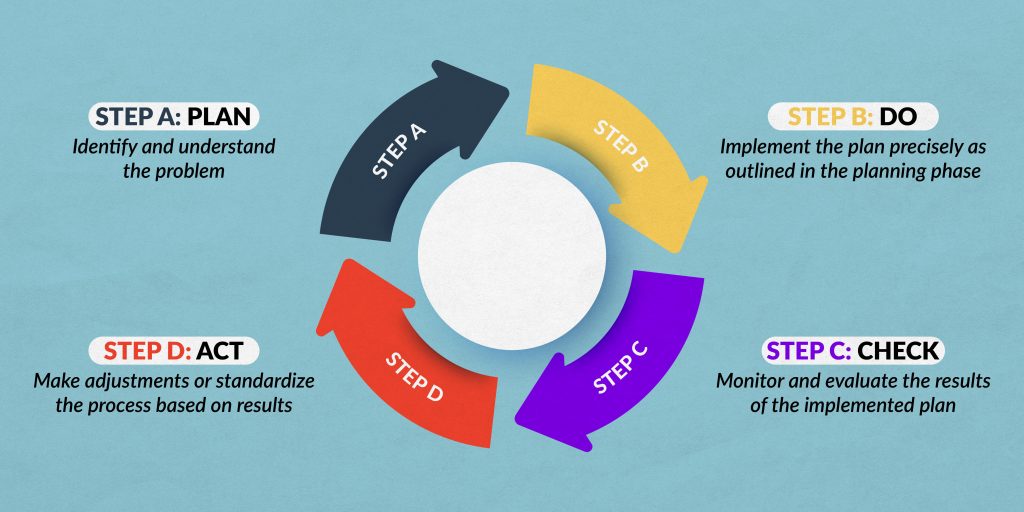

The term PDCA is the abbreviated form of the steps, which is Plan-Do-Check-Act. It is a valuable problem-solving method for organizations and individuals seeking to continuously improve their processes and outcomes. It promotes a structured and data-driven approach to problem-solving and quality management.

Plan

In this first step, a detailed plan is developed to identify and understand the problem or goal. This includes setting objectives, defining metrics for success, and devising a strategy or action plan to achieve the desired outcome.

Do

Once the plan is in place, the next step is to execute the plan. This involves putting the proposed changes or actions into practice. It’s important to implement the plan precisely as outlined in the planning phase.

Check

The check phase involves monitoring and evaluating the results of the implemented plan. Data is collected and analyzed to determine whether the desired objectives are being met. This step assesses the effectiveness of the actions taken.

Act

Based on the findings from the check phase, decisions are made on how to proceed. If the objectives are met or exceeded, the process can be standardized and adopted. If not, adjustments are made to the plan, and the cycle begins again, incorporating lessons learned from the previous iterations.

PDCA (Plan-Do-Check-Act) vs PDSA (Plan-Do-Study-Act)

As mentioned earlier, Deming revised “Check” to “Study” in the methodology as he deemed that “Check” emphasizes observation rather than analyzing.

PDCA (Plan-Do-Check-Act) and PDSA (Plan-Do-Study-Act) are two similar methodologies that share a common goal of improving processes and achieving continuous improvement. However, they differ slightly in their terminology and application.

Plan

The “Plan” phase in PDSA is similar to PDCA. You create a plan, set objectives, and design the process or changes you want to implement.

Do

Like PDCA, the “Do” phase involves executing the plan, putting the proposed changes into action.

Study

In PDSA, the third phase is “Study.”

During this phase, you gather data and study the results to determine whether the objectives were achieved and whether the changes made a positive impact.

Act

The final phase in PDSA is “Act.” Based on the findings from the “Study” phase, you make decisions on how to proceed. If the objectives are met, you standardize the process. If not, you make necessary adjustments to the plan and repeat the cycle.

How PDCA/PDSA Cycle Can Improve Business Processes

The PDCA or PDSA cycle is a continuous and iterative process of problem solving and improvement. Which means, this process doesn’t only mean to fix problems one time, but continuously improve it further until it exhausts all solutions, providing the best possible result.

Continuous Improvement

PDCA promotes a culture of continuous improvement within an organization. By repeatedly cycling through the phases, processes can evolve and become more efficient over time.

Structured Approach

The PDCA Cycle provides a systematic and structured approach to problem-solving and process improvement. It ensures that changes are well-planned, executed, and evaluated.

Data-Driven Decision Making

The “Check” phase of PDCA involves data collection and analysis. This data-driven approach allows organizations to make informed decisions based on actual performance rather than assumptions.

Improved Quality

PDCA helps organizations identify and eliminate defects or errors in processes. This leads to higher product or service quality, increased customer satisfaction, and potentially fewer customer complaints.

Resource Efficiency

Through the PDCA process, organizations can identify resource waste and optimize resource allocation, resulting in cost savings.

Process Optimization

The primary focus of both cycles is to optimize processes, making them more efficient, effective, and reliable. This can lead to improved quality, reduced costs, and enhanced customer satisfaction.

PDCA / PDSA compared to Six Sigma

PDCA / PDSA and Six Sigma are two distinct methodologies that organizations often use to improve processes, enhance quality, and achieve better results. While both approaches aim to drive continuous improvement, there are differences in its concept, framework, focus, and skill sets. Here are the key differences between PDCA and Six Sigma:

Framework

PDCA / PDSA follows a simple four-step cycle: Plan, Do, Check/Study, Act. It is a cyclic and iterative approach that emphasizes continuous improvement through incremental changes.

Six Sigma follows a more structured framework, often referred to as DMAIC (Define, Measure, Analyze, Improve, Control) DMAIC is used for improving existing processes.

Focus

PDCA: PDCA is a versatile framework that can be applied to various aspects of an organization, including process improvement, problem-solving, and project management.

Six Sigma: Six Sigma is primarily focused on reducing defects, improving process efficiency, and achieving measurable financial results. It uses statistical tools and techniques to identify and eliminate process variations.

Certification

PDCA has no specific roles or formal certification programs associated with PDCA. It is a general improvement concept that can be applied by individuals at all levels of an organization.

Six Sigma has defined roles, including Green Belts, Black Belts, and Master Black Belts, who receive training and certification in Six Sigma methodologies. These roles are responsible for leading and implementing Six Sigma projects within an organization.

PDCA / PDSA compared to Total Quality Management (TQM)

While PDCA / PDSA is focused on specific improvements, Total Quality Management (TQM) is an approach on a broader scale which includes the organization, departments, and employees.

Scope

PDCA/PDSA is a specific improvement methodology that follows a four-step cycle (Plan-Do-Check/Study-Act). It is used for problem-solving and making incremental improvements to processes.

TQM: TQM is a broader quality management philosophy and approach that encompasses a wide range of principles and practices. It is focused on improving the overall quality of an organization’s products, services, and processes.

Application

PDCA/PDSA is typically used for specific projects or process improvements. It provides a structured framework for addressing particular issues or challenges.

TQM is applied organization-wide and seeks to embed a culture of quality and continuous improvement in every aspect of the organization, from leadership to frontline employees.

Focus

PDCA/PDSA focuses on the cyclic nature of improvement, with a focus on iterative problem-solving and incremental changes.

While TQM focuses on a holistic approach to quality, focusing on customer satisfaction, process improvement, employee involvement, and leadership commitment.

Businesses that used PDCA/PDSA that Gain Positive Results

Toyota is often cited as one of the pioneers of the PDCA cycle. The company’s Toyota Production System (TPS) incorporates PDCA principles to improve manufacturing processes and reduce waste. Toyota’s commitment to continuous improvement through PDCA has made it a leader in the automotive industry.

McDonald’s used PDCA to optimize its drive-thru operations. By implementing small, iterative changes in processes and technology, they were able to reduce wait times, improve order accuracy, and enhance the customer experience.

Conclusion

The PDCA/PDSA cycle, Six Sigma, and Total Quality Management are proven structured, data-driven problem solving methodologies that help organizations improve and optimize their business processes. Businesses like Toyota and McDonald’s have optimized their processes delivering positive results for their customers, products, and organization.