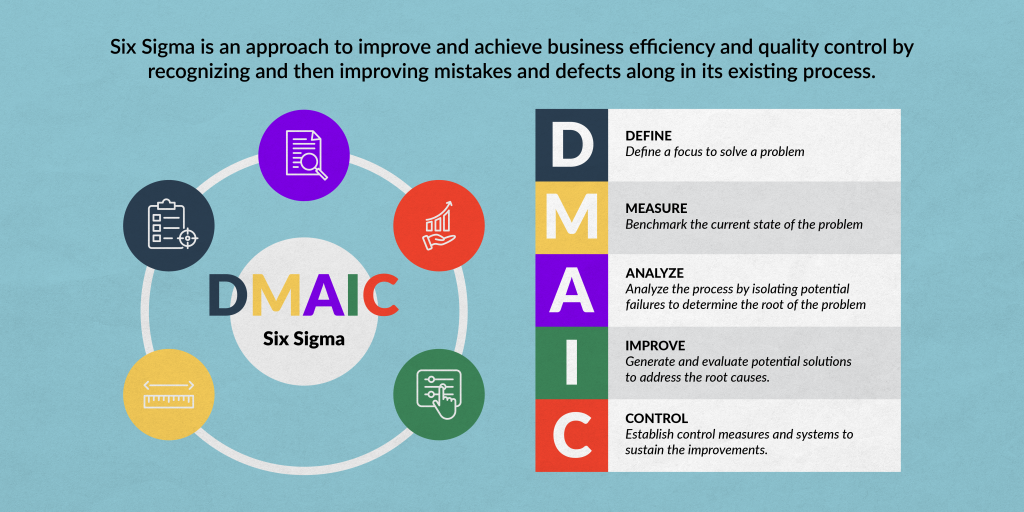

Six Sigma is a methodology created by Bill Smith, along with Mikel Harry in the 1980s when they worked as engineers at Motorola. Six Sigma is an approach to improve and achieve business efficiency and quality control by recognizing and then improving mistakes and defects along in its existing process. In this article, we will talk about the 5 phases of the Six Sigma methodology, the supplementary benefits of the problem-solving methodology in your business, and how to get a Six Sigma certification.

Defining Six Sigma

Six Sigma originated as a means of quality improvement and control in manufacturing. It is an ideology made that all business processes can be measured, optimized, and improved. The methodology has evolved ever since its first implementation. It has superseded manufacturing, in which the methodology is applicable in improving and optimizing customer satisfaction, retention, products, and the overall business efficiency process.

The Five Steps of Six Sigma

The methodology of Six Sigma involves a series of steps called DMAIC, shortened as defining, measuring, analyzing, improving and controlling. Companies that have implemented the Six Sigma methodology have boosted efficiency and profits.

First Step: Define

In the Six Sigma methodology, the “Define” phase is the initial step in any improvement project. Its primary objective is to set a clear and well-defined scope for the project and to identify the problem or opportunity that the team, lead by a Six Sigma expert, wishes to address

It begins by pinpointing a specific problem or challenge within a process. This problem is typically something that affects product quality, customer satisfaction, cost efficiency, or another critical aspect of the business.

- Identify the problem or opportunity for improvement.

- Define the project scope and objectives.

- Determine the stakeholders and their expectations.

- Create a project charter that outlines the project’s purpose, goals, and team members.

Second Step: Measure

After defining the problem in the “Define” phase, the next step in the methodology is often referred to as the “Measure” phase. In this phase, the team focuses on benchmarking the current state of the process or system. Benchmarking involves assessing the current performance of the process that is related to the identified problem.

- Collect data related to the process to understand its current performance.

- Identify key process metrics (KPIs) and measures.

- Analyze data to assess process capability and establish a baseline.

- Create process maps and flowcharts to visualize the current process.

This step involves data collection, performance assessment, and considering potential hindrances in the process.

Third Step: Analyze

The “Analyze” phase is the third step in the methodology, where the team focuses on analyzing the process by isolating each input or potential reason for failures to determine the root cause of the problem.

- Identify the root causes of the problems or defects identified in the Measure phase.

- Use statistical tools and techniques to analyze data and uncover the causes of variation.

- Develop hypotheses and test them to validate the root causes.

- Prioritize the most significant causes to address.

Fourth Step: Improve

After analyzing the root cause of the problem, the team moves forward into the next step: improvement. Data gathered from performance assessments and hypothesis tests are utilized in order to perform the necessary improvements within the process.

- Generate and evaluate potential solutions to address the root causes.

- Select the best solutions and develop an implementation plan.

- Pilot test the improvements to ensure they work as expected.

- Implement the improvements across the entire process.

Fifth, final step: Control

The “Control” phase is the fifth and final step in the methodology. The team ensures the solution is fool-proof by implementing preventive and control measures to avoid the event of any regression or relapse.

- Establish control measures and systems to sustain the improvements.

- Monitor the key process metrics to ensure they remain within acceptable limits.

- Develop a control plan to prevent the recurrence of the original problems.

- Train and empower team members to sustain the improvements.

A control plan is often developed, outlining the specific steps and responsibilities for maintaining control over the process. It includes details about who is responsible for what, what needs to be monitored, and how often.

What is Lean Six Sigma?

Lean Six Sigma is a comprehensive methodology, combining the process of Lean Enterprise and Six Sigma.

The Lean enterprise, or referred to simply as Lean originated from Toyota Motor Corporation’s Toyota Production System that achieves further improvement of business efficiency by eliminating non-value added tasks, which are labeled as “wastes”.

With the incorporation of Six Sigma, hence the methodology is named “Lean Six Sigma”, with the goal to identify and increase the value of products, goods, or services to customers.

This methodology strives to reduce resource expenditures such as time, effort, and labor, while maintaining a standard of production and organizational process, without compromising.

The Supplementary Benefits of Learning Six Sigma

Learning and implementing Six Sigma can offer a wide range of supplementary benefits in addition to its primary goal of improving process efficiency and reducing defects. These supplementary benefits can have a significant positive impact on both individuals and organizations.

Efficient Approach to Problem Solving

Six Sigma equips individuals and teams with advanced problem-solving tools and techniques, such as DMAIC (Define, Measure, Analyze, Improve, Control), which can be applied not only to work-related issues but also to personal challenges and decision-making.

Data-Driven Decision-Making

Data is key. Six Sigma emphasizes the importance of data and analytics in decision-making. This skill can be valuable in various aspects of life, including financial planning, health decisions, and personal goal setting.

Continuous Improvement Mindset

Learning Six Sigma fosters a culture of continuous improvement. This mindset can extend beyond the workplace, encouraging individuals to seek better ways of doing things in their personal lives and communities.

Developing leadership skills

Six Sigma projects often require individuals to lead and manage teams. This experience can enhance leadership skills and prepare individuals for higher responsibilities within their organizations.

Cost Savings

Organizations that implement Six Sigma often see significant cost savings through reduced defects and process efficiency improvements. This can lead to financial stability and growth, which can benefit employees through job security and potential bonuses.

Customer Satisfaction

Improved product and service quality resulting from Six Sigma initiatives can lead to higher customer satisfaction, which can positively affect an organization’s reputation and market share.

Six Sigma Certification and Rankings

The Six Sigma certification is given to esteemed individuals and professionals that have undergone and understood the course of the Six Sigma program. The certifications are awarded by a hierarchy called the belt system. In case you’re wondering, yes, similar to the belt system used in martial arts and karate.

White Belt

The white belt certification establishes basic knowledge and introduction to the Six Sigma methodology, but has not undergone further training in understanding the concept and ideology. This certificate esteems individuals to be part of the Six Sigma team.

Yellow Belt

The next level to the hierarchy, the Yellow Belt is bestowed upon when an individual or professional has undergone sufficient training sessions. With the Yellow Belt certificate, it indicates that individuals are equipped with the knowledge and skills to lead on small projects.

Green Belt

Individuals or professionals that have undergone comprehensive Six Sigma training are bestowed with the Green Belt certification. These professionals are esteemed to lead bigger projects and potentially become a Six Sigma team leader.

Black Belt

As we are all aware, the Black Belt is at the top of the belt hierarchy in martial arts and karate, categorizing as masters and champions.

Same goes for the Sigma Six certification. The Black Belt is the highest certification that an individual can receive. Individuals possessing the Black Belt certificate are tenured in the ideologies and concept of Sigma Six, providing them the honors to lead a team on larger, complex projects.

Where to Get Six Sigma Certification in the Philippines

In the Philippines, Filipino individuals and professionals can get a Six Sigma certification from Six Sigma PH, with over 15,000 clients and help businesses realize cost savings over 1.2 Billion Pesos. Six Sigma PH offers self-paced e-Learning, enabling you to learn the cost-saving ideologies and concepts of Six Sigma at your own pace, especially when things get busy.

Conclusion

Six Sigma is a supplementary skill to learn for individuals, professionals, leading to efficiency for a business. Whether you are an individual learning the concepts and ideologies of Six Sigma, or a business looking to train future leaders, Six Sigma can equip you and your team with efficient, data-driven problem solving.